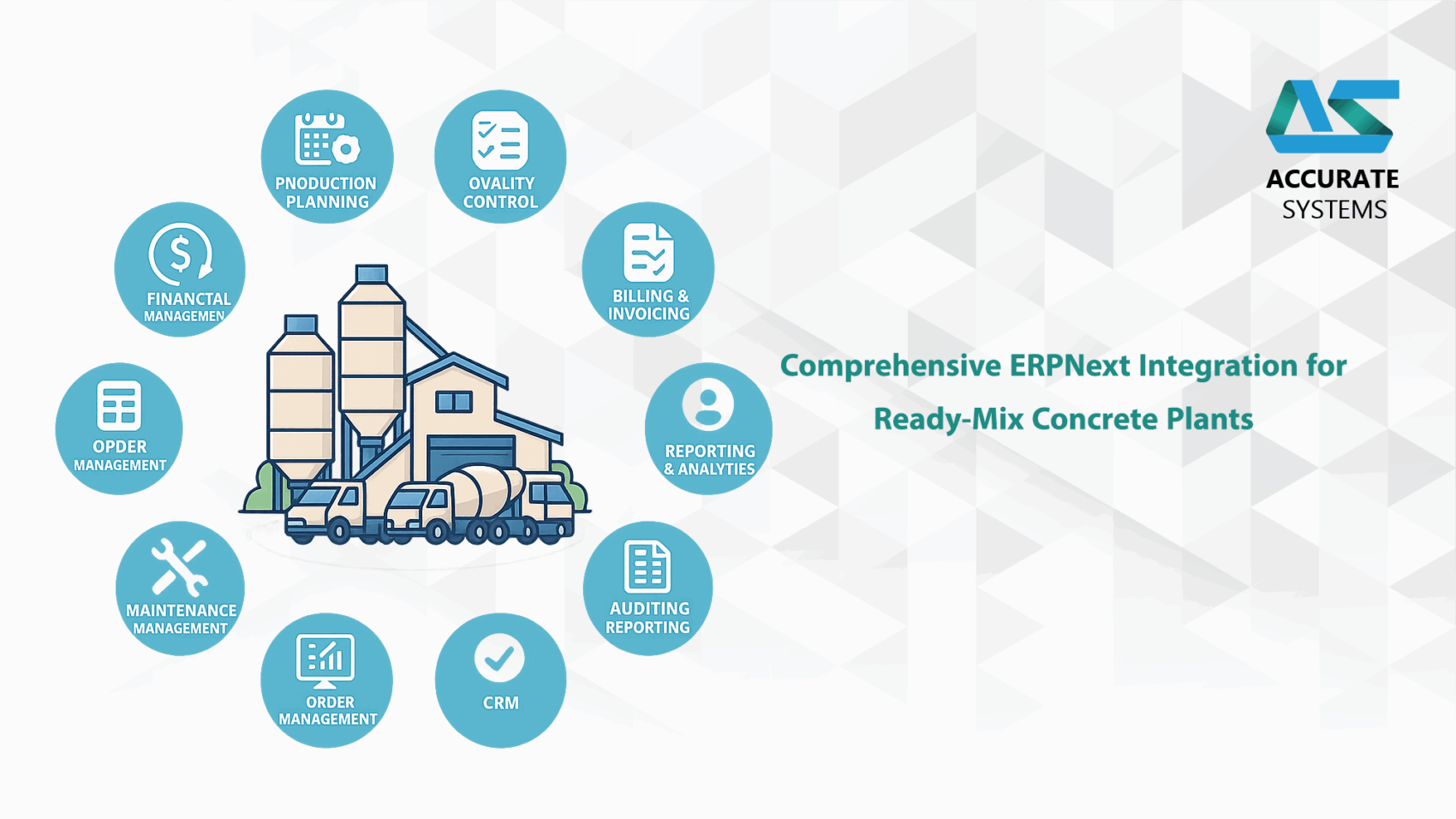

Introduction: Why ERPNext is the Ideal Platform for Ready-Mix Concrete Operations

Ready-mix concrete production is a fast-paced, resource-intensive business that demands real-time coordination between production, logistics, finance, and customer service. ERPNext provides a unified, cloud-based solution that integrates all business functions into one intelligent system.

With the addition of industry-specific extensions, ERPNext supports every aspect of ready-mix operations—from production planning to delivery, inventory tracking, and invoicing. Below is a breakdown of how each ERPNext module contributes to optimized performance in a concrete batching environment.

1. Production Planning | تخطيط عمليات التصنيع

ERPNext enables detailed planning of daily production based on sales orders, project timelines, and fleet availability.

- Mix design BOM integration

- Batch scheduling linked to delivery windows

- Load balancing between multiple plants

2. Inventory Tracking | متابعة الإنتاج

Stay updated on the availability and usage of raw materials like cement, aggregates, and admixtures.

- Real-time inventory dashboards

- Silo integration and consumption logs

- Auto-reordering based on threshold levels

3. Order Management | إدارة الطلبات

Streamline order entry and scheduling with CRM and production linkage.

- Quote-to-order conversion

- Customer-specific mix design preferences

- Delivery slot booking

4. Financial Management | الإدارة المالية

Gain full control over cost centers, revenue, and project profitability.

- Project-based costing

- Cash flow and receivables tracking

- Integration with Saudi VAT and ZATCA compliance

5. Maintenance Management | إدارة الصيانة

Track plant equipment, mixers, and truck health with preventive schedules.

- Service logbooks for pumps, silos, and vehicles

- Spare parts inventory

- Alerts for scheduled maintenance or faults

6. CRM | التسويق

Manage leads, follow-ups, and client engagement all in one place.

- Track client preferences and projects

- Record site visits and follow-up reminders

- Manage key account relationships

7. Reporting & Analytics | التقارير والتحليلات

Turn data into decisions with real-time dashboards and trend analysis.

- KPIs: cycle time, truck turnaround, cost per m³

- Custom financial, production, and delivery reports

- Export-ready for internal and board-level reporting

8. Billing & Invoicing | الفوترة والمبيعات

Accelerate payment cycles with automated, compliant invoicing.

- ZATCA Phase 2 e-invoicing with QR and UUID

- Auto-billing by cubic meter and mix type

- Partial invoicing for phased deliveries

9. Quality Control | إدارة الجودة

Ensure that every batch meets specifications and regulatory compliance.

- Log test results (slump, compressive strength)

- Certificates of conformity and test reports

- Integrate QC with production logs

10. Fleet Management | إدارة الشاحنات والتوصيل

Optimize dispatch and fleet operations to reduce delays and maximize delivery efficiency.

- Live truck tracking and route planning

- Trip scheduling based on load and mix design

- Driver logs and fuel usage tracking

Conclusion: One Platform to Run Your Entire Ready-Mix Operation

With ERPNext, ready-mix producers no longer need separate systems for inventory, dispatch, finance, and production. All modules communicate seamlessly to improve uptime, customer service, and cost control.

Whether you’re managing a single plant or a national fleet, ERPNext gives you the tools to deliver concrete on time, every time—while maintaining full operational visibility.

#ERPNext #ConcreteERP #ReadyMixConcrete #BatchingPlant #ProductionPlanning #FleetManagement #InventoryTracking #ZATCACompliance #DigitalConstruction